Views: 793 Author: Site Editor Publish Time: 2023-06-29 Origin: Site

In simple terms, the production process of self-adhesive labels includes three processes of pre-press, printing and post-press processing. Among them, the post-press processing process involves more processes, including glazing, lamination, bronzing, die-cutting, and slitting. and so on. In the whole production process, the ambient temperature has a great influence on the quality and performance of self-adhesive label products. For example, in the machinery industry standard JB/T 9111-1999 <Self-adhesive Label Printing Machine>, the printing environment temperature is required to be 20℃±2 ℃, the press and publication industry standard CY/T 93-2013 <Printing Technology Self-adhesive Label Quality and Inspection Method> requires that the test temperature be 23℃±5℃. However, at present, the actual situation of many printing companies is difficult to reach the suitable temperature for printing, which will cause a series of product quality problems.

Problem 1-Material

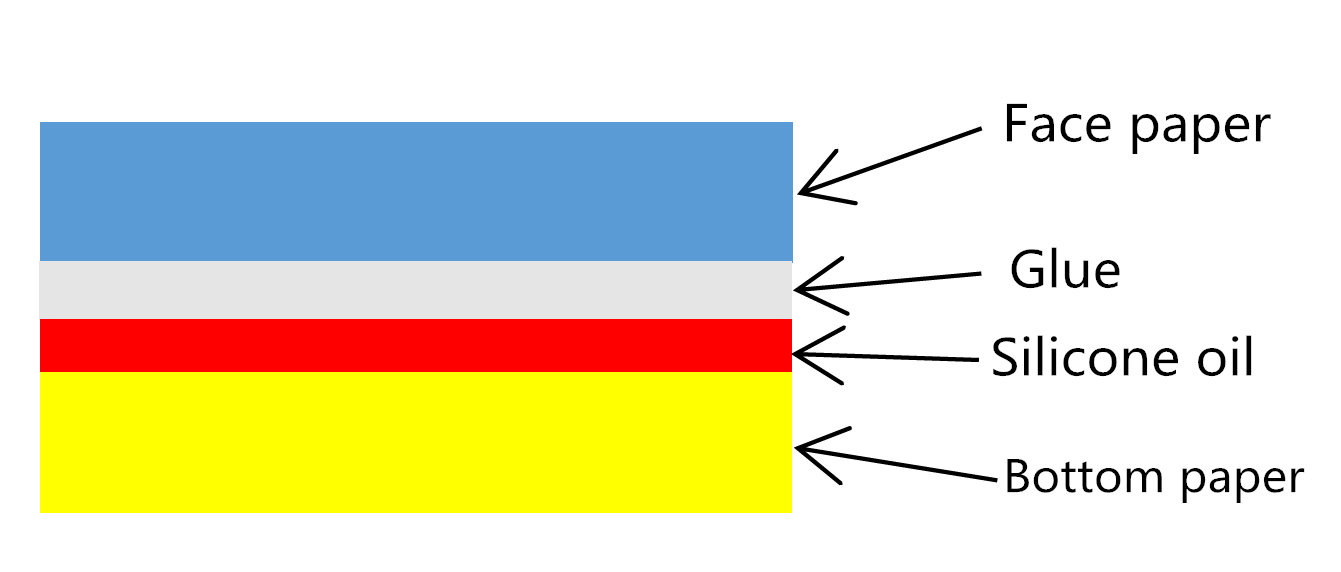

As shown in Figure 1, most of the adhesives in the glue layer of self-adhesive labels are organic polymers, which have a high dependence on temperature. In other words, their mechanical properties and viscoelasticity will be affected by the temperature change of the external environment. certain influence. Under normal circumstances, the self-adhesive label material manufacturer will choose to configure adhesives with different initial viscosity and persistent viscosity according to the actual application of the labeling temperature and the temperature of the product storage environment to adapt to different use environments and further satisfy customers' product demand.

Problem 2-Printing

Ambient temperature also has a great influence on printing. Especially in winter, in an environment without heating and air conditioning, the outside temperature is low, resulting in low temperatures in machinery, equipment, inks and printing materials. Taking offset printing as an example, the printing principle is to complete the ink transfer through the balance of water and ink, that is, the printing plate cylinder first contacts with the water roller, so that the non-graphic hydrophilic part of the printing plate is first watered, and then contacts the ink roller, so that The graphic part is inked, and then the ink of the image part on the printing plate is first transferred to the blanket, and the blanket roller transfers the ink image to the printing material under the action of the pressure roller. If the temperature of the machine equipment is low, it will seriously affect the transfer effect. At the same time, the ink temperature is low, which will lead to high viscosity and low fluidity of the ink, so that the ink cannot flow well between the ink rollers, resulting in unsmooth ink transfer,uneven, resulting in uneven ink color on the printing surface, which in turn affects the image effect on the printing material and reduces the amount of printed matter. As shown in Figure 2 and Figure 3, they are schematic diagrams of local defects of two different products. Among them, there are printing defects on the far right of the barcode in Figure 2, and there are printing defects on the uppermost side of the magenta solid ink in Figure 3.

Problem 3-Cutting

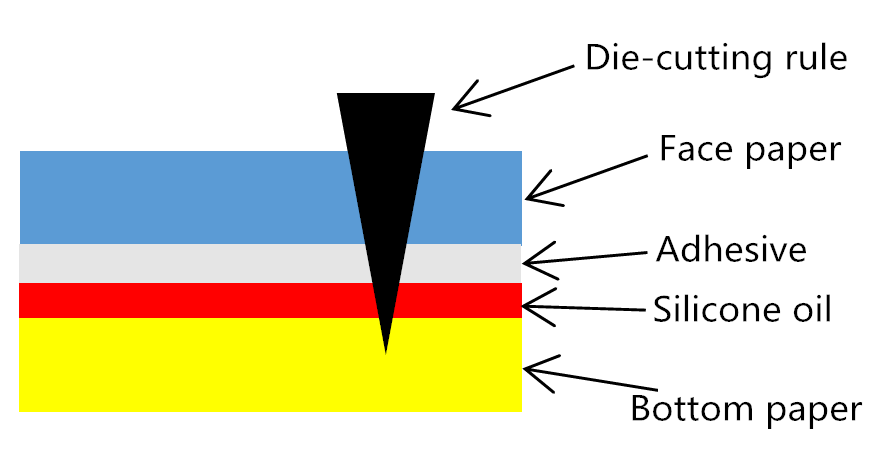

The quality of the die-cutting effect is not only the problem of the die-cutting knife plate itself and the pressure problem, but also the external ambient temperature will also affect the die-cutting production process. Accurate die-cutting means that the die-cutting knife just cuts off the surface material and glue layer (as shown in Figure 4), while improper die-cutting can be divided into shallow die-cutting (as shown in Figure 5) and deep die-cutting (as shown in Figure 6) two cases, where a shallow die cut causes the label to be carried away by the scrap, and a deep die cut causes the liner to break or be carried away by the label. When the ambient temperature is low, the fluidity of the adhesive in the self-adhesive material decreases, resulting in the inability to cut off the glue layer during the die-cutting process, and the label will be discarded, which will not only reduce the production speed, but also affect the product. quality.

Solution 1-Materil

First of all, we must fully understand the object being posted. Know whether the material of the sticker is paper, plastic, metal, or glass, etc.; know whether the surface of the sticker is flat or curved; know whether the environment where the sticker is placed is high or low temperature, whether there will be long-term sun exposure or rain Drenching, etc... These factors will not only affect the selection of self-adhesive label surface materials, but also affect the matching of adhesives. For example, certain foods, beverages or pharmaceuticals are filled and labeled at low temperature. Generally, the adhesive will harden at low temperature and reduce the viscosity. In order to avoid flying marks and falling marks due to the poor viscosity of the adhesive after pasting, it is necessary to use a self-adhesive label that meets the low temperature labeling requirements and has a high initial viscosity. Material.

Secondly, before printing, it is necessary to transport and store the self-adhesive materials in the production printing workshop 24 hours in advance, so that the temperature and humidity of the self-adhesive materials and the printing workshop can reach a balance state, and the temperature of the printing workshop can be kept at 18°C to 25°C. Humidity can be maintained at 50% to 65%.

Solution 2-Printing

The transfer effect of the ink will directly affect the quality of the printed matter. There are mainly the following methods to improve the influence of low temperature on ink:

One is to place the ink on the radiator or next to the radiator to make it warm up slowly and gradually return to its original state. In case of emergency, hot water can be used for external heating. The specific method is: pour hot water into the basin, then put the ink barrel (box) in the hot water, but be sure to prevent steam from intruding, take it out after a while, and open the cover Stir well and use. There are also some printing companies in the north that have purchased incubators, put the ink in the incubator, and take it out for use before going on the machine.

The second is to add 5% to 10% thinner varnish or viscosity reducer to the ink to increase the fluidity of the ink. However, it should be noted that the amount added should not be too much, otherwise there will be problems such as blooming of the imprint and non-drying of the imprint. For stacked color products, the viscosity of the second color needs to be reduced. As shown in

Figure 3, according to the color sequence, magenta ink can be printed first, and then yellow ink can be printed, that is, the magenta ink is more viscous and the yellow ink is less viscous.

In addition, the ink will also have a thick phenomenon at normal temperatures, because the consistency of the ink reflects the rheological properties of the ink to a certain extent. If the thickening phenomenon is not caused by external factors, it can be summarized as the following two reasons: one is caused by the strong thixotropy in the internal structure of the original ink, which can still be used after being stirred to restore its original state; Deteriorated ink caused by improper storage cannot be used again.

The third is to increase the temperature of the workshop to meet the printing conditions. In such an environment, the machine equipment and ink will meet the adaptation conditions with the increase of the workshop temperature, reducing the viscosity of the ink and increasing the fluidity.

The fourth is to let the printing machine run empty for a period of time, so that heat can be generated by the rotation and extrusion of the ink roller, and then the ink is put on for printing.

Solution 3-Cutting

Cutting off the surface material and glue layer of the self-adhesive material is the key to accurate die-cutting. Adhesives commonly used in the glue layer of self-adhesive materials include acrylic water-based latex and hot melt adhesive. Due to the low cohesion of acrylic water-based latex, it is easier to die-cut, and it has no special requirements for die-cutting tools and die-cutting environments, and the quality of die-cutting can be well guaranteed. However, the cohesive force between the hot melt adhesive molecules is relatively large, and the requirements for die-cutting tools and the environment are relatively strict. Especially at low temperatures, the activity of the hot melt adhesive is relatively weak. If the force is too small, it is easy to cause "flying marks".

The improvement methods are as follows: one is to place a heater beside the equipment, which can be placed before the die-cutting and waste discharge to heat the surface of the material; the other is to add a heating plate or heating roller to the die-cutting equipment to increase the surface temperature of the material; Place the semi-finished products that need to be die-cut in a warm environment for a period of time, so that the temperature of the self-adhesive label material rises to reduce the phenomenon of label drop; the fourth is to make full use of the previous process. If the product that needs to be coated, it will be heated by the coating machine The pre-coated film is adhered to the self-adhesive label surface paper, and the semi-finished product just after lamination is used for die-cutting firstly, and the residual temperature on the surface of the semi-finished material is fully utilized to improve the problem of label drop and waste discharge caused by die-cutting due to low temperature. question.

Final

To sum up, in the cold winter, if the ambient temperature of the production workshop is low, printing companies will encounter a series of problems in the production process of self-adhesive labels. This paper analyzes the temperature from three aspects: raw materials, printing, and die-cutting. Low impact on the production process of self-adhesive labels, and list the corresponding improvement methods. I hope that the experience shared in this article can be helpful to everyone, so that the production of self-adhesive labels in printing companies can survive the winter smoothly.

Contact me for sticker paper price, cast coated sticker paepr, semi-glossy sticker paper, offset sticker paper, PP/PET/PVC sticker paper and etc.

Thank you for your attention.

If you have any interests about it, pls contact us freely.

Attn:Hans He

Whatsapp/WeChat:+0086 13676974117

Email:sales07@dtpapergroup.com

Website:www.dtpapergroup.com