Views: 12 Author: Susan Publish Time: 2024-09-12 Origin: Site

Uncoated woodfree offset paper is a staple in the printing industry, known for its versatility and high-quality performance. This type of paper is widely used for books, brochures, office papers, and more. In this blog post, we'll dive into the intricate manufacturing process that goes into producing uncoated woodfree offset paper. From raw material selection to the final product, each step is crucial in ensuring the paper meets the required standards for quality and performance.

1. Raw Material Selection

The journey of uncoated woodfree offset paper begins with the selection of raw materials. Unlike traditional wood-containing paper, woodfree paper uses alternative fiber sources such as cotton linters, linen, hemp, or chemically processed wood pulps like bleached chemi-thermomechanical pulp (BCTMP) and bleached hardwood kraft pulp (BHK). These materials are chosen for their strength, brightness, and ability to create a smooth surface suitable for offset printing.

2. Pulping

Once the raw materials are selected, they undergo pulping. This process involves mechanically grinding the fibers to separate them from the lignin, a complex organic polymer that binds the cells together in trees. Depending on the source material, different pulping processes may be employed:

Mechanical Pulping: Used for BCTMP, where wood chips are ground into fibers using refiners.

Chemical Pulping: Employed for BHK, which involves cooking the wood chips in a solution of chemicals to dissolve lignin and leave cellulose fibers.

3. Bleaching

After pulping, the resulting fibers are often dark and contain residual lignin. To achieve the desired whiteness, the pulp undergoes bleaching. This process removes any remaining lignin and brightens the fibers. Various bleaching agents, including hydrogen peroxide and ozone, can be used depending on the desired properties of the final paper.

4. Refining

Refining is a mechanical treatment that further improves the fiber bonding by increasing the surface area of the fibers. This process enhances the paper's strength and smoothness, making it more suitable for printing. The degree of refining directly affects the paper's opacity, brightness, and printability.

5. Formation of Paper Stock

The refined fibers are mixed with water to form a slurry, known as furnish. This mixture is then pumped onto a moving wire mesh, where water drains through, leaving a mat of fibers on the mesh surface. As more water is removed, the fibrous mat becomes thicker and starts forming a continuous sheet of paper stock.

6. Pressing and Drying

The wet paper web is pressed between rollers to remove additional water and improve its consolidation. The pressing process also enhances the paper's smoothness and density. Following pressing, the paper enters the drying section, where it passes over a series of steam-heated dryer drums. These drums gradually remove moisture, bringing the moisture content down to around 6-8%.

7. Calendering

To achieve the desired surface smoothness and texture, the dried paper is calendered. This process involves passing the paper between a series of highly polished rollers under significant pressure. Calendering can be done once or multiple times to produce different finishes, such as gloss, matte, or satin.

8. Coating (Optional)

Although we're discussing uncoated woodfree offset paper, it's worth noting that some variations might include a light coating to enhance specific properties like ink receptivity or surface strength. However, true uncoated paper skips this step entirely.

9. Finishing Operations

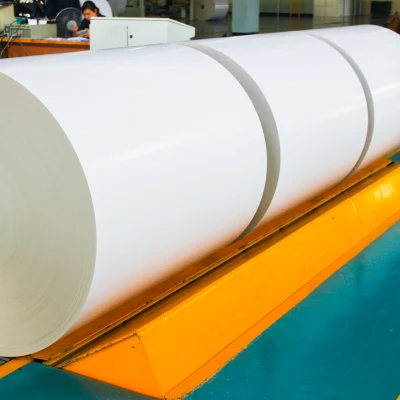

The final steps involve various finishing operations to prepare the paper for use. These may include:

Slitting: Cutting the wide paper web into narrower rolls or sheets.

Winding: Rolling the paper onto cores for transportation and storage.

Reel to Sheet Conversion: Cutting the paper roll into individual sheets if needed.

Quality Control Checks: Ensuring the paper meets specifications for thickness, weight, brightness, smoothness, and other critical parameters.

10. Packaging and Distribution

Once all finishing operations are complete, the paper is packaged and prepared for distribution. It is carefully wound onto cores, wrapped in protective materials, and shipped to printing facilities worldwide. Proper packaging ensures that the paper remains undamaged during transit and storage.

Environmental Considerations

The manufacturing process of uncoated woodfree offset paper has come a long way in incorporating environmentally friendly practices. Manufacturers are increasingly adopting sustainable sourcing of raw materials, reducing water consumption, minimizing waste, and utilizing renewable energy sources. Additionally, advancements in chemical management have led to the development of eco-friendly bleaching processes that reduce the environmental footprint significantly.

Conclusion

The manufacturing process of uncoated woodfree offset paper is a testament to human ingenuity and technological advancement. Each step, from raw material selection to the final packaging, plays a vital role in producing a high-quality product that meets the demands of the printing industry. As consumer preferences shift towards sustainability, manufacturers continue to innovate, ensuring that woodfree offset paper remains a key player in the world of printed media while minimizing its environmental impact.

If you need uncoated woodfree paper, contact us freely.

Susan He

Whats App/Wechat:008619939956123

Double Tree Industry Group Co., Ltd