Views: 4529 Author: Jeff Cui Publish Time: 2023-12-29 Origin: Site

SELF ADHESIVE STICKER LABEL

A self-adhesive label is a composite material made of thin film, paper, or special materials, coated with adhesive on the back, and coated with silicone backing paper as protective paper. It is processed through printing, die-cutting, and other processes to complete the finished product label. When in use, simply peel off the backing paper and press lightly to apply it to the surface of various substrates. Alternatively, the labeling machine can be used to automatically label on the production line. Compared with traditional labels, self-adhesive labels do not require brushing or pasting, are pollution-free, can save labeling time, and can be conveniently and quickly applied in various occasions. By using different fabrics, adhesives, and backing paper, various types of labels can be processed and applied to materials that cannot be applied to general paper labels. It can be said that self-adhesive labels are a universal type of label.

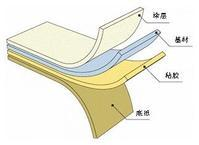

Structure of self-adhesive labels

The structure of self-adhesive material is composed of three parts from the surface, namely surface material, adhesive, and backing paper, but from the manufacturing perspective

From the perspective of technology and quality assurance, self-adhesive materials consist of seven parts: surface coating, surface material, coating layer

Adhesive, backing paper, and back coating or printing

The so-called surface material refers to the surface material, which receives printed graphics and text on the front, adhesive on the back, and is ultimately applied to the surface to be glued

The material on the sticker. The type of surface material depends on the final application and printing process. The surface material should be able to adapt to printing and printing

Printing, with good inkability and sufficient strength to accept various processing such as die-cutting, waste removal, longitudinal cutting, punching, and

Labeling, etc. The surface gloss and color consistency of the surface material, as well as the uniformity of density, determine the average ink absorption of the adhesive material Uniformity also determines the color difference of the same batch of label prints.

Application areas in the packaging industry: marking labels, postal parcels, letter packaging, transportation goods labeling, envelope address labels; Commodity industry: price labels, product description labels, shelf labels, barcode labels, drug labels; Chemical industry: Paint material labeling, gasoline engine oil product packaging labeling, and labeling of various special solvent products; Electronic and electrical labels used in the electronic and electrical industry: There are numerous durable adhesive labels attached to various types of electrical appliances, which have a large unit area and a large quantity. In addition, self-adhesive labels are widely used as explanatory labels for industrial products (computers, etc.), which has also driven the demand for self-adhesive labels. Logistics labels in the logistics industry: In recent years, the logistics industry is emerging in China, and there is an increasing demand for variable information printed labels in modern logistics, such as storage and transportation labels, luggage labels, supermarket labels, etc. Medical labels used in the pharmaceutical industry: Drug packaging is increasingly using self-adhesive labels. With the sale of over-the-counter drugs on the shelves, drug manufacturers and consumers are paying more attention to drug packaging, which will greatly encourage drug manufacturers to accelerate the transition from traditional labels to self-adhesive labels. Adhesive stickers are a widely used type of advertising material in the advertising industry. They work best with instant engraving machines to create products that are widely used in lightboxes, sign making (mounting), vehicle advertising, permanent signage, signs, computer-cut patterns, showcase patterns, display board making, and more. The back adhesive of this product is acrylic solvent pressure-sensitive adhesive with excellent adhesion. It is made of high molecular weight calendered polyethylene base rubber, which has the characteristics of multi color, strong color retention, and uniform color. It has good weather resistance and pollution resistance, good anti shrinkage performance, and a service life of more than three years. It is a cost-effective method for ordinary door decoration.

How to choose

Small stickers are often an important reflection of a company's image and brand, playing a crucial role in showcasing product quality and arousing consumer desire to purchase. So what are the precautions when choosing a label or a sticker label?

Issues to pay attention to when selecting label materials

1.For cylindrical bottles, especially those with a diameter less than 30MM, careful selection of materials is necessary.

2.f the label size is too large or too small, attention should be paid to conducting actual tests.

3. If the object being pasted has an irregular surface or even a spherical surface, there are specific considerations for the type of label material, thickness, and adhesive.

4. Some rough surfaces, such as corrugated cardboard boxes, can affect labeling, and the gloss on the surface of corrugated cardboard boxes can also have an impact.

5. Automatic labeling machine labels, and labeling tests can be conducted if necessary.

Even if the label is labeled at room temperature, it is important to pay attention to whether it has experienced high temperatures during export transportation and use.

7. Excessive water or oil environment can affect the characteristics of adhesives, and attention should be paid to the environment and temperature of label placement.

8. Sometimes plasticizers may seep out of the surface of soft PVC, so special attention should be paid to selecting the appropriate adhesive.

Thank you for your attention.

If you have any interests about it, pls contact us freely.

Attn:Jeff Cui

Whatsapp/WeChat:+0086 15838015073

Email:sales06@dtpapergroup.com

Website:www.dtpapergroup.com