Views: 18 Author: Cara Gao Publish Time: 2024-07-05 Origin: Site

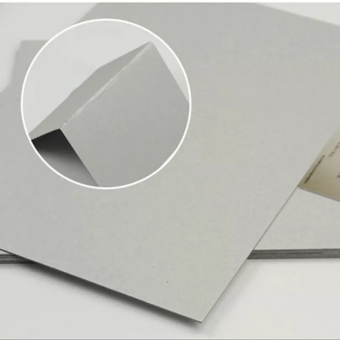

Duplex board grey back is a versatile and durable material that has gained popularity in various industries, from packaging to construction.

How is duplex board grey back made?

The manufacturing process of duplex board grey back involves several steps, starting with the selection of raw materials. The primary raw materials used in the production of duplex board grey back are wood pulp, water, and chemicals. The wood pulp is typically sourced from softwood trees, such as pine or spruce, which are known for their long fibers and high cellulose content. These long fibers are essential for creating a strong and durable material.

Once the wood pulp is obtained, it is mixed with water and chemicals in a large vat called a pulper. The chemicals used in this process include bleaching agents, sulfites, and surfactants, which help to break down the wood fibers and remove impurities. The mixture is then stirred vigorously to create a homogenous pulp slurry.

Next, the pulp slurry is fed into a paper machine, where it is formed into a continuous sheet. The paper machine consists of several components, including a headbox, wire section, press section, and dryer section. The headbox distributes the pulp slurry evenly onto a moving belt called a wire. As the wire moves, water is drained from the pulp, leaving behind a wet paper web.

The wet paper web then passes through the press section, where it is pressed between rollers to remove more water and increase its strength. Finally, the paper web enters the dryer section, where it is dried using steam-heated cylinders. The drying process removes any remaining moisture, resulting in a strong and stable material.

After drying, the paper web is coated with a layer of grey back, which gives the duplex board its distinctive appearance and adds to its durability. The grey back is typically made from a mixture of clay, titanium dioxide, and other additives, which are applied to the surface of the paper using a coating machine. The coated paper is then calendared, or polished, to achieve a smooth and uniform finish.

In conclusion, the manufacturing process of duplex board grey back involves selecting raw materials, mixing them with water and chemicals, forming the pulp into a paper web, pressing and drying the web, applying a grey back coating, and calendaring the finished product. The resulting material is strong, durable, and versatile, making it a popular choice for a wide range of applications. Its eco-friendliness and recyclability also make it an attractive option for businesses looking to reduce their environmental impact. the manufacturing process of duplex board grey back involves selecting raw materials, mixing them with water and chemicals, forming the pulp into a paper web, pressing and drying the web, applying a grey back coating, and calendaring the finished product. The resulting material is strong, durable, and versatile, making it a popular choice for a wide range of applications. Its eco-friendliness and recyclability also make it an attractive option for businesses looking to reduce their environmental impact.

What are the uses of duplex board grey back?

One of the primary uses of duplex board grey back is in packaging applications. Its strength and durability make it an ideal material for creating corrugated boxes and shipping containers. These containers are used to transport goods of all kinds, from food and beverages to electronics and furniture. The duplex board grey back provides excellent protection against impacts and moisture, ensuring that the contents remain safe during transit.

Duplex board grey back is also used in printing and advertising. It is commonly used as a substrate for posters and signs, providing a smooth and uniform surface for printing. The grey back coating on the duplex board gives the printed material a professional appearance and helps to enhance the colors and images. Additionally, the durability of the duplex board ensures that the printed material will last for an extended period without fading or tearing.

In conclusion, the uses of duplex board grey back are diverse and varied. Its strength, durability, and eco-friendliness make it an ideal choice for a wide range of applications, from packaging and construction to printing and advertising. As more industries become aware of the benefits of this material, its popularity is likely to continue to grow.

Double Tree Paper Industry Group Co.,Ltd

Email:topexports@vip.sina.com

Whatsapp/wechat:008613674933715